- Home

- 8-VFS-1 VACUUM FILTRATION SYSTEM (7691)

8-VFS-1 VACUUM FILTRATION SYSTEM (7691)

Related Products

VB4 VACUBERM by SIROCCO (6177)

VB4 VACUBERM by SIROCCO (6177)

$318.00

Are you washing and need to contain the wash water? The Sirocco VacuBerm FEATURES:● Fits 1.5" and 2" vac hose INCLUDES:● 1 – SandSnake● 1 – SiltFilterSPECIFICATIONS:● Required 50-75 CFM for 5-8 GPM

STEEL EAGLE FURY 2400 VACUUM DISK (6079)

$445.00

This is an excellent attachment to have when using the FURY 2400. This sturdy disk will attach to your system to remove liquids. Lay near water to be cleared and turn on vac.

STEEL EAGLE FURY 2400 VAC 24" SURFACE CLEANER & CAPTURE TOOL

STEEL EAGLE FURY 2400 VAC 24" SURFACE CLEANER & CAPTURE TOOL

$2,775.00

The Steel Eagle Fury 2400 Series provides a one-step unit that pressure washes, rinses and instantly recovers the waste stream for proper treatment. The Fury 2400 clean and capture systems will expand your opportunities for higher-paying, environmentally sensitive jobs, and that leads to more profits! Steel Eagle Clean & Capture Tools recov...

ST-36 SLUDGE PUMP KITS by SUTTNER

ST-36 SLUDGE PUMP KITS by SUTTNER

$170.60

PLEASE NOTE!!! The 1 1/2" spiroflex hose is NOT AVAILABLE and there is no solid ETA on additional availability. We recommend utilizing a discharge hose from a local pool store. Applications: Attaches to pressure washer and turns it into a high output pump. Great for flood cleanup, car wash pits, draining pools or chemical spills. Features: • ...

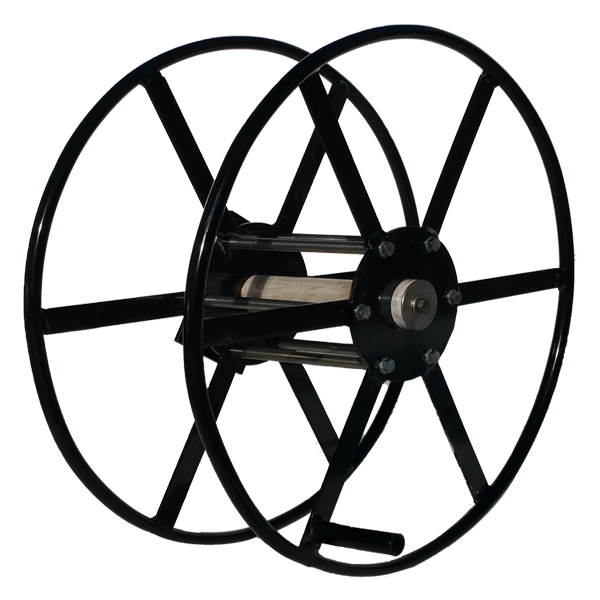

VAC HOSE STORAGE REEL by SIROCCO

VAC HOSE STORAGE REEL by SIROCCO

$559.00

This Sirocco vac hose storage reel is an excellent option for those using larger diameter hoses in reclaim situations.

SC21V 21" VAC SURFACE CLEANER by SIROCCO (6035)

$2,499.00

Sirocco Vacuum Surface Cleaner – 3 Port Vacuum System Extremely fast flat-surface cleaner with re-capture! Control over spray from pressure washing sidewalks, warehouse floors, tile surfaces and more. Sanitize when you clean by using hot water (up to 250° F) and leave the floor clean and almost dry! Add our filtration for Re-use and have the ult...

LEAF / SAND TRAP 30 GALLON by SIROCCO (7108)

$1,100.00

SIROCCO 30 GALLON LEAF/SAND TRAP FEATURES:● Triple-step powder-coated tank (rust-proof and resistant to harsh chemicals!)● Slide-in filter screen is completely chemical resistant and easily cleanable● Removable mud bucket with mesh leaf bag● 1½” CamLock drain● 2” CamLock vac hose fittings● Stainless hardware The optional, but highly recommended...

MOSMATIC 21" RECOVERY SURFACE CLEANER 5000 PSI (7138)

$1,955.00

Connect a vacuum unit to the FL-AH520 surface cleaner and get cleaning results like never before. This surface cleaner will recover dirt and grime from most any cleaning job. Ideal for indoor / outdoor cleaning. Clean gas stations, industrial food processing plants, garages, warehouses and more. This series features four 4" stainless steel, ...

IPC EAGLE VACUUM SYSTEM (7100)

IPC EAGLE VACUUM SYSTEM (7100)

$1,989.00

This industrial grade wet vac is super durable and efficient. Constructed mostly of polyethylene , it will stand up to strong cleaners. It has a 24-gallon capacity with an auto pump-out feature that discharges up to 40 GPM. The GC290 model features a two-motor vacuum with 211 cfm. This unit rolls effortlessly on 4 caster units. It is lighte...

OIL SOCKS CASE OF 15 - 3" X 8' (9102)

$150.00

OIL SOCKS CASE OF 15 - 3" X 8'

OIL SOCK - SINGLE SOCK 3" X 4' (9101)

$6.00

OIL SOCK - SINGLE SOCK 3" X 4'

OIL SOCKS CASE OF 30 (3" X 4') (9100)

$165.00

OIL SOCKS CASE OF 30 (3" X 4')